100% Zero Carbon

Element Zero has created a mineral processing platform that utilises renewable energy to convert iron ore to iron and other future facing metal ore into metal.

This non-aqueous electrochemical process allows Element Zero to process the full spectrum of ores. The technology has been tested successfully on iron ore, nickel, tin, titanium and interestingly on converting silica to silicon metal.

- Read More

The low temperature allows Element Zero to run this process on intermittent renewables such as wind, solar, and hydropower, while using 30-40% less energy than the current dominant coal and gas based processes and produces a superior purity product.

One Platform – Multiple Metals

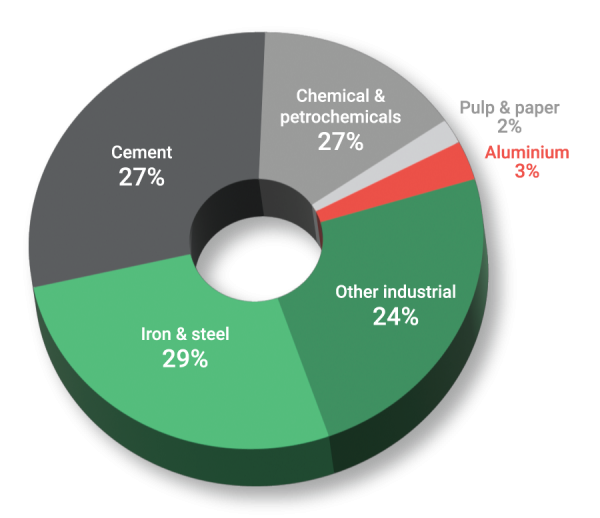

Element Zero’s technology targets removal of nearly 30% of global industrial emissions.

2022 Global Industrial Carbon Emissions

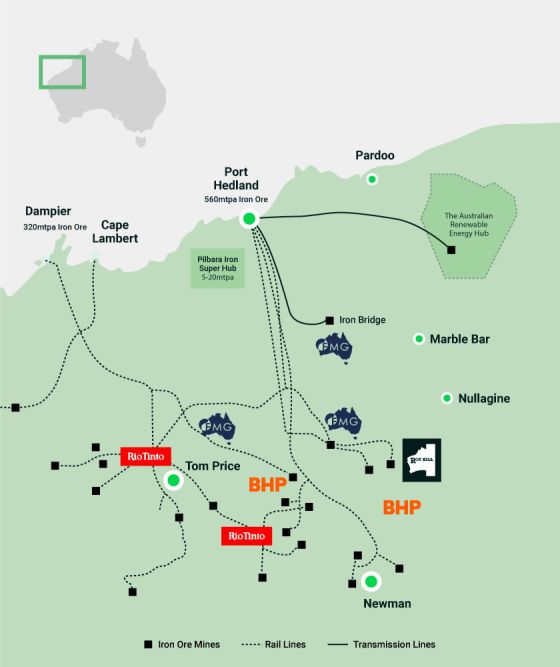

Pilbara Iron Super Hub,

Port Hedland, Australia

Prime location adjacent to 50% of global iron exports, our platform is able to deliver cost reductions to iron ore and energy metal suppliers and the world’s leading customers including core North and South Asian Markets.

-

5 million tonnes per annum of iron ore feed sourced from major ore companies

-

Expanding in stages to 20 million tonnes per annum (circa US$9 billion revenue)

-

Renewable electricity from Australian Renewable Energy Hub and new dedicated sources

-

Planned location at Boodarie Strategic Industrial Area

-

Exporting to North and Southeast Asia

Why We’re Different

-

01

Platform Approach

Element Zero has developed a mineral processing platform. Rather than looking at one single mineral, we aim to process the entire periodic table of elements, except for carbon.

-

02

Energy Efficiency and Selectivity

Element Zero has achieved the highest energy efficiency among its competitors, while high selectivity of the process allows us to produce high purity materials.

-

03

Maximising Revenue Streams by Capturing By-Products

Impurities from iron ore can be extracted and captured including silica, alumina, titania, phosphate, and manganese, among others.

-

04

Modular Approach

Element Zero’s technology is a one-pot single step process allowing for full scalability, both up and down and modular build.

-

05

Simplicity and Low Capital Expenditures

Element Zero uses inexpensive and abundant materials, we don’t need membranes or expensive elements. Element Zero’s reactors are simple and cost effective. -

06

Uniquely Capable Team and Ideal Geography

Our team is comprised of global leaders in electrochemistry, electroreduction and finance. Element Zero’s Port Hedland plant has access to over 1 gigawatt of power and 25% of the worlds iron shipping capacity.