Renewable Energy and Unique Chemistry Enables a Zero Carbon Producer of Iron and Future Facing Metals.

Element Zero’s processes use renewable energy and unique chemistry to produce iron, nickel, silicon and other future facing metals, with 30-40% less energy per tonne of iron than coal and gas based processes without the CO2.

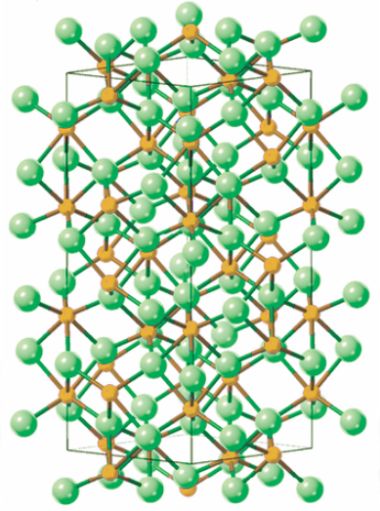

Starting with iron ore, we have a commercial path to reduce 7-9% of global CO2 emissions. Our patents cover the overall process and its unique chemistry as well as the complete circuit design for mineral processing incorporating a unique electrolyte.

One Platform – Multiple Metals

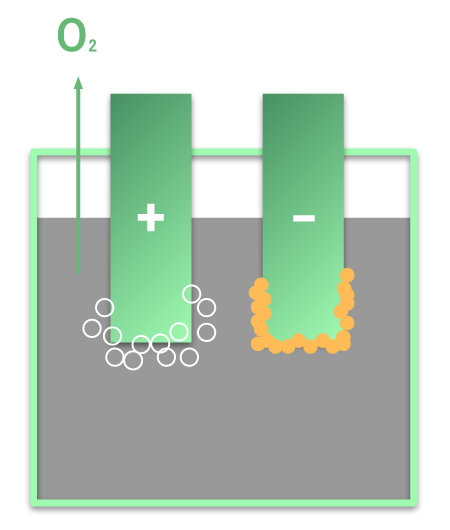

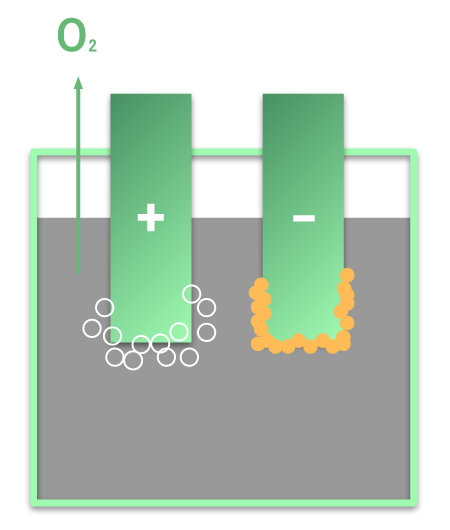

Electroreduction converts iron ore to high purity iron.

-

Iron ore and other minerals dissolve in 15 –30 minutes with full dissolution within 60 minutes.

-

Electroreduction converts iron ore to high purity iron ~98%.

-

Superior efficiency with 30 – 40% less energy consumption compared to traditional processing pathways.

-

Intermittent energy (wind and solar) can be used in the process resulting in green iron.

-

The technology can process low grade (30% Fe) to high grade (72% Fe) iron ore.

-

Low operating temperature in the range of 250 – 300°C enables rapid ramp up and ramp down of the processing capacity.

-

No membrane is needed.

Circular Nature of the Process.